A Couple of Disasters, and Back to the Drawing Board on the Irish Red

My highly anticipated (at least, by me) Christmas beer - one featuring almost 20% crystal malt, plus a gallon and a half of first runnings reduced to a quart and a half of syrup, plus some dark Belgian candi sugar - turned out to be an unmitigated disaster. Rather than the huge caramel flavor I was hoping for, I ended up with a horribly metallic, astringent, mouth-coating mess - indicating that I managed to contaminate this beer somewhere along the way. While I knew that aging wasn't going to fix things, I did leave it around for a few weeks, just to be sure... and it only got worse.

Fudge. Down the drain it went.

I'm part of a group of a dozen or so brewers from around the country who do a holiday beer exchange. They ship a case of beer to my house; I reassemble those cases so that everyone gets one bottle of each, then ship them back to their respective senders. This year, we decided to move our exchange back to late January (Happy New Beer, you guys!), but with my Christmas beer a failure, I still had to come up with a substitute. Fortunately, we had decided to get away from a strictly holiday/spiced/winter warmer theme this time around, and instead have each member showcase a beer that represented their style of brewing. As luck would have it, the next beer I had planned not only fit this bill perfectly, but was also a quick one to turn around - my Kentucky Common.

The last time I brewed this beer, it was a great success. It was looking like this iteration would be, as well; while I didn't have it quite carbed up, the tasting glass I had pulled was pretty darned delicious. I was having carbonation issues due to the gas poppet not seating properly, but had planned to fix this on Saturday morning, prior to brewing that day.

Sadly, on Saturday morning, I woke up to another disaster - the bottom of my keezer was full of beer. I've been in the habit of leaving my picnic taps hooked up, and yep, I apparently left this one pressed slightly against the keezer wall. All five gallons of delicious beer were gone.

To put it mildly, I have found myself on a bit of a losing streak.

The temptation to say "screw brewing today" was strong, but I did have a recipe that I was excited to try... and I needed something to send to the exchange (a two plus month old, over the hill IPA didn't seem like the ideal choice), so I chose to soldier on.

Way back when I first starting putting together my own recipes, one of my first tries was for was a "big" Irish red ale (i.e. higher gravity and bitterness than the style called for). That original recipe (with a minor tweak or two) made an excellent beer. However, I was never quite happy with the color - it was simply more brown than I wanted. My goal was to have a beautiful, ruby red, malty beer with a little caramel flavor, perhaps a hint of roastiness. In other words, everything that is good in an Irish red, just a tiny bit more of it.

Jonah, one of my brewing buddies, the first time I brewed this beer (four years ago) - versus how he looks today.

I have previously gotten far too cute in an effort to chase that elusive ruby red color; my most recent try featured a blend of crystal malts, melanoiden malt, and carared... and yielded a beer that still wasn't quite what I wanted in color, and definitely missed the mark in flavor. Rather than continue to tweak this and that, I decided to go completely back to the drawing board.

Many of the best Irish reds are pretty simple - a British base malt, some crystal malt, a very small amount roasted barley for color. I decided to start there.

The frustrating thing about red color is that it is terribly difficult to predict and measure. Unlike with anything else on the sliding SRM scale of yellow, amber, brown, and black, red cannot really be represented by a number.

I have always before used Maris Otter in my Irish reds. Maris Otter has been perhaps my favorite malt for some time; I find US two row to be boring, so unless I had a need for Pilsner malt, I would turn to Maris Otter.

A couple of years ago, I brewed my first beer with Golden Promise, and it has continued to grow on me. Golden Promise is now my base malt of choice for hoppy beers and for anything lighter in color, while I reserve Maris Otter more and more for beers with more malt presence, or those of darker colors. It didn't take much pondering for me to decide to build this new recipe around Golden Promise.

Some homework told me that C20 and C40 yielded the most red color of the crystal malts, and since I have long been a fan of "layering" crystal malts (i.e. combining two of them to yield a fuller, more complex flavor than you can get from a single crystal malt alone), it was natural for me to go with both.

Add in a little roasted barley, and I had an idea for my grain bill. I ran my idea past the email list of brewers I'm a part of (many of which are on that Christmas exchange), and they as always had some great input. Several of them suggested that I look into Red X malt from Bestmalz; the connection was made this this grain is apparently malted with magic, as it does in fact yield some tremendous red color. One respected brewer went so far as to suggest a grain bill of 90% Red X, 10% crystal, and call it a "new" Irish red. While that was intriguing, I wasn't ready to go quite that far... but I was, in fact, sold on the idea of Red X.

After a fair amount of balancing (and multiple checks to figure out what the actual color of the roasted barley from the LHBS really was), I came up with a recipe that I felt really good about. Homework tells me that while 12-14 SRM can look reddish, 16-18 is supposed to be the pinnacle of the intense ruby color that I've been trying to achieve. Beersmith says that my recipe should work out to 16.2 SRM, which seems perfect.

I should get some caramel flavor from the crystal malts, as well as from the Red X, and the small amount of roasted barley should impart just a touch of dryness. As is my custom, I tossed in four ounces of flaked barley for the magic (real or imagined) that it gives to head formation and retention.

Hops are Challenger and Fuggles, both of which are earthy/spicy/floral types that fit the style exactly and are among my favorite choices.

I had to substitute WLP028 (Edinburgh ale) for my intended WLP004 (Irish ale), thanks to the LHBS being a week behind on yeast deliveries due to some inclement weather. I also had to mail order the Red X, as neither LHBS carried the stuff - but my imagination was too taken by the idea to skip it.

At any rate, brew day rolled around, and after feeling sorry for myself for a bit after discovering the loss of my Kentucky Common (and playing a couple of rounds of Titanfall on the Xbox to vent a little frustration), I got going on brewing the Irish red.

This bag supposedly contains red magic. We shall see.

As always, I prepped my cooler with the Brew Bag, secured it with bungies, and dumped the grains in. I have raved about it before, but this is one of the single best improvements I have made to my process.

My target mash temperature was 148 degrees F; after stirring, I felt like I was pretty well where I wanted to be. Sadly, I wasn't able to say the same for my ten minute pH reading - my target was 5.42, but the reading was 5.20. This is two beers in a row that have had low pH issues; apparently, the water company has made some drastic changes, and I'm going to need to get a new water report.

After draining to the kettle, I (with the help of my boys) added the first wort hops. I then batch sparged, drained that, and started the boil. Due to a little overzealous squeezing of the bag, I ended up with a tad more liquid than I had planned, so I did adjust the boil time accordingly. Soon enough, it was time to toss my chiller into the boil to sanitize, then make the fifteen minute hop addition; this time, only Jonah came with me, so he got to add all of the hops for this step.

With five minutes left in the boil, I went out to toss in my whirlfloc tablet, and naturally, got to witness the death of my flame - I was out of propane. Oh, well. I tossed the whirlfloc in, anyway; fun fact - whirlfloc tablets actually fizz when they enter the wort, a phenomenon that I had not noticed in the past due to the roiling of the surface during boiling. I went ahead and stirred for a bit, waiting ten minutes before I started chilling. I figured that would be close enough on the hops, and surely the whirlfloc would work at temperatures just under boiling.

Chilling was a breeze, as it always is. The Hydra chiller from JaDeD got me down to about seventy degrees F in just a tad over five minutes. As is now my custom, I collected the first (and hottest) six gallons of chilling water to save for cleaning the chiller. Why not reuse it?

After bringing the beer inside, I took my original gravity reading - 1.065, which was dead on. Yes, that is my sanitized hydrometer floating in the kettle. I can read it just fine, and skipping the thief/sample tube process means that I have one fewer item to have to clean and sanitize. For reference, I obtain my final gravity reading in the same manner (by floating the hydrometer in the keg/bottling bucket).

Go ahead. Tell me why this is a bad idea.

From that point, I dumped everything into my carboy, aerated with pure O2, and pitched my yeast. I set my STC-1000 for 18.3 degrees C (aka 65 degrees F) and called it a night. Well, I called it a night after cleaning everything else up.

For the record, the wort had some nice red hues when pouring it into the carboy. Obviously, it's way too early to tell much about the color; unfermented wort is darker than fermented beer, and five and a half gallons in a carboy is darker than twelve ounces in a glass. The wort itself was pretty tasty, but again, it's far too early to be able to tell much.

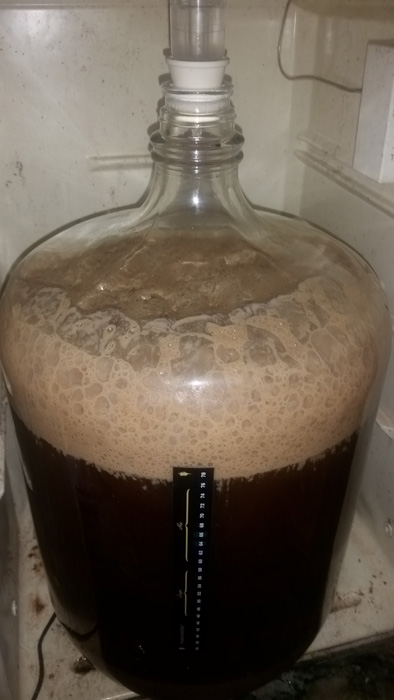

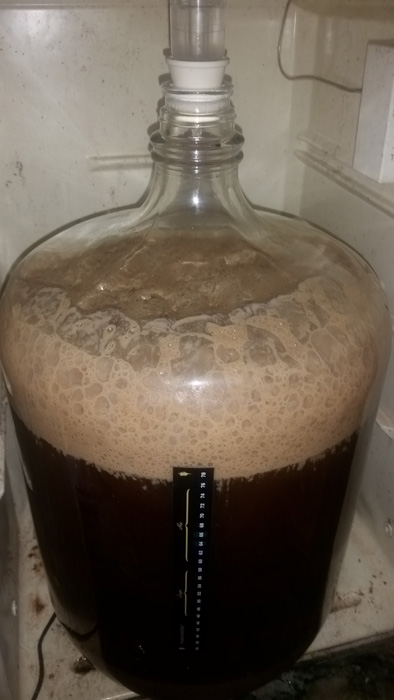

Naturally I did check the beer first thing in the morning, and I found a great krausen and a bubbling airlock. As of the time of this posting, it has been bubbling away merrily for three days now. I plan to give the beer a couple of days once it hits terminal gravity, then cold crash, add gelatin, keg it up, and get it carbed as quickly as I can. I'm guessing that I should be able to turn it around in, oh, ten days or so from grain to glass.

Carboy picture included because this is a beautiful sight I never tire of.

Will I finally capture that elusive ruby red color? Will I manage to hit the flavor profile that I'm looking for? Will I at the very least manage to brew something that won't result in my third failed batch in a row - and reduce me to the ignominy of having to purchase local craft beer for us in the holiday exchange? Stay tuned to find out!

Share this recipe on reddit

Permalink

Tags for this post: disaster, lost beer, Irish red, ale, red x, redx

1 Comments

Well that's a terrible streak of bad luck.

Hopefully this beer turns out great, the recipe sure does sound good.

posted by muzakx on 1/26/2017 at 09:45:18 AM

Fudge. Down the drain it went.

I'm part of a group of a dozen or so brewers from around the country who do a holiday beer exchange. They ship a case of beer to my house; I reassemble those cases so that everyone gets one bottle of each, then ship them back to their respective senders. This year, we decided to move our exchange back to late January (Happy New Beer, you guys!), but with my Christmas beer a failure, I still had to come up with a substitute. Fortunately, we had decided to get away from a strictly holiday/spiced/winter warmer theme this time around, and instead have each member showcase a beer that represented their style of brewing. As luck would have it, the next beer I had planned not only fit this bill perfectly, but was also a quick one to turn around - my Kentucky Common.

The last time I brewed this beer, it was a great success. It was looking like this iteration would be, as well; while I didn't have it quite carbed up, the tasting glass I had pulled was pretty darned delicious. I was having carbonation issues due to the gas poppet not seating properly, but had planned to fix this on Saturday morning, prior to brewing that day.

Sadly, on Saturday morning, I woke up to another disaster - the bottom of my keezer was full of beer. I've been in the habit of leaving my picnic taps hooked up, and yep, I apparently left this one pressed slightly against the keezer wall. All five gallons of delicious beer were gone.

To put it mildly, I have found myself on a bit of a losing streak.

The temptation to say "screw brewing today" was strong, but I did have a recipe that I was excited to try... and I needed something to send to the exchange (a two plus month old, over the hill IPA didn't seem like the ideal choice), so I chose to soldier on.

Way back when I first starting putting together my own recipes, one of my first tries was for was a "big" Irish red ale (i.e. higher gravity and bitterness than the style called for). That original recipe (with a minor tweak or two) made an excellent beer. However, I was never quite happy with the color - it was simply more brown than I wanted. My goal was to have a beautiful, ruby red, malty beer with a little caramel flavor, perhaps a hint of roastiness. In other words, everything that is good in an Irish red, just a tiny bit more of it.

Jonah, one of my brewing buddies, the first time I brewed this beer (four years ago) - versus how he looks today.

I have previously gotten far too cute in an effort to chase that elusive ruby red color; my most recent try featured a blend of crystal malts, melanoiden malt, and carared... and yielded a beer that still wasn't quite what I wanted in color, and definitely missed the mark in flavor. Rather than continue to tweak this and that, I decided to go completely back to the drawing board.

Many of the best Irish reds are pretty simple - a British base malt, some crystal malt, a very small amount roasted barley for color. I decided to start there.

The frustrating thing about red color is that it is terribly difficult to predict and measure. Unlike with anything else on the sliding SRM scale of yellow, amber, brown, and black, red cannot really be represented by a number.

I have always before used Maris Otter in my Irish reds. Maris Otter has been perhaps my favorite malt for some time; I find US two row to be boring, so unless I had a need for Pilsner malt, I would turn to Maris Otter.

A couple of years ago, I brewed my first beer with Golden Promise, and it has continued to grow on me. Golden Promise is now my base malt of choice for hoppy beers and for anything lighter in color, while I reserve Maris Otter more and more for beers with more malt presence, or those of darker colors. It didn't take much pondering for me to decide to build this new recipe around Golden Promise.

Some homework told me that C20 and C40 yielded the most red color of the crystal malts, and since I have long been a fan of "layering" crystal malts (i.e. combining two of them to yield a fuller, more complex flavor than you can get from a single crystal malt alone), it was natural for me to go with both.

Add in a little roasted barley, and I had an idea for my grain bill. I ran my idea past the email list of brewers I'm a part of (many of which are on that Christmas exchange), and they as always had some great input. Several of them suggested that I look into Red X malt from Bestmalz; the connection was made this this grain is apparently malted with magic, as it does in fact yield some tremendous red color. One respected brewer went so far as to suggest a grain bill of 90% Red X, 10% crystal, and call it a "new" Irish red. While that was intriguing, I wasn't ready to go quite that far... but I was, in fact, sold on the idea of Red X.

After a fair amount of balancing (and multiple checks to figure out what the actual color of the roasted barley from the LHBS really was), I came up with a recipe that I felt really good about. Homework tells me that while 12-14 SRM can look reddish, 16-18 is supposed to be the pinnacle of the intense ruby color that I've been trying to achieve. Beersmith says that my recipe should work out to 16.2 SRM, which seems perfect.

I should get some caramel flavor from the crystal malts, as well as from the Red X, and the small amount of roasted barley should impart just a touch of dryness. As is my custom, I tossed in four ounces of flaked barley for the magic (real or imagined) that it gives to head formation and retention.

Hops are Challenger and Fuggles, both of which are earthy/spicy/floral types that fit the style exactly and are among my favorite choices.

I had to substitute WLP028 (Edinburgh ale) for my intended WLP004 (Irish ale), thanks to the LHBS being a week behind on yeast deliveries due to some inclement weather. I also had to mail order the Red X, as neither LHBS carried the stuff - but my imagination was too taken by the idea to skip it.

At any rate, brew day rolled around, and after feeling sorry for myself for a bit after discovering the loss of my Kentucky Common (and playing a couple of rounds of Titanfall on the Xbox to vent a little frustration), I got going on brewing the Irish red.

This bag supposedly contains red magic. We shall see.

As always, I prepped my cooler with the Brew Bag, secured it with bungies, and dumped the grains in. I have raved about it before, but this is one of the single best improvements I have made to my process.

My target mash temperature was 148 degrees F; after stirring, I felt like I was pretty well where I wanted to be. Sadly, I wasn't able to say the same for my ten minute pH reading - my target was 5.42, but the reading was 5.20. This is two beers in a row that have had low pH issues; apparently, the water company has made some drastic changes, and I'm going to need to get a new water report.

After draining to the kettle, I (with the help of my boys) added the first wort hops. I then batch sparged, drained that, and started the boil. Due to a little overzealous squeezing of the bag, I ended up with a tad more liquid than I had planned, so I did adjust the boil time accordingly. Soon enough, it was time to toss my chiller into the boil to sanitize, then make the fifteen minute hop addition; this time, only Jonah came with me, so he got to add all of the hops for this step.

With five minutes left in the boil, I went out to toss in my whirlfloc tablet, and naturally, got to witness the death of my flame - I was out of propane. Oh, well. I tossed the whirlfloc in, anyway; fun fact - whirlfloc tablets actually fizz when they enter the wort, a phenomenon that I had not noticed in the past due to the roiling of the surface during boiling. I went ahead and stirred for a bit, waiting ten minutes before I started chilling. I figured that would be close enough on the hops, and surely the whirlfloc would work at temperatures just under boiling.

Chilling was a breeze, as it always is. The Hydra chiller from JaDeD got me down to about seventy degrees F in just a tad over five minutes. As is now my custom, I collected the first (and hottest) six gallons of chilling water to save for cleaning the chiller. Why not reuse it?

After bringing the beer inside, I took my original gravity reading - 1.065, which was dead on. Yes, that is my sanitized hydrometer floating in the kettle. I can read it just fine, and skipping the thief/sample tube process means that I have one fewer item to have to clean and sanitize. For reference, I obtain my final gravity reading in the same manner (by floating the hydrometer in the keg/bottling bucket).

Go ahead. Tell me why this is a bad idea.

From that point, I dumped everything into my carboy, aerated with pure O2, and pitched my yeast. I set my STC-1000 for 18.3 degrees C (aka 65 degrees F) and called it a night. Well, I called it a night after cleaning everything else up.

For the record, the wort had some nice red hues when pouring it into the carboy. Obviously, it's way too early to tell much about the color; unfermented wort is darker than fermented beer, and five and a half gallons in a carboy is darker than twelve ounces in a glass. The wort itself was pretty tasty, but again, it's far too early to be able to tell much.

Naturally I did check the beer first thing in the morning, and I found a great krausen and a bubbling airlock. As of the time of this posting, it has been bubbling away merrily for three days now. I plan to give the beer a couple of days once it hits terminal gravity, then cold crash, add gelatin, keg it up, and get it carbed as quickly as I can. I'm guessing that I should be able to turn it around in, oh, ten days or so from grain to glass.

Carboy picture included because this is a beautiful sight I never tire of.

Will I finally capture that elusive ruby red color? Will I manage to hit the flavor profile that I'm looking for? Will I at the very least manage to brew something that won't result in my third failed batch in a row - and reduce me to the ignominy of having to purchase local craft beer for us in the holiday exchange? Stay tuned to find out!

Share this recipe on reddit

| Batch Size (gallons) | 5.5 | ||||||||||||||||||||||||||||

| Efficiency | 74% | ||||||||||||||||||||||||||||

| Recipe type | All Grain | ||||||||||||||||||||||||||||

| Style | 15A. Irish Red Ale | ||||||||||||||||||||||||||||

| Original Gravity | 1.065 | ||||||||||||||||||||||||||||

| Final Gravity | 1.013 | ||||||||||||||||||||||||||||

| ABV | 6.83% (basic) / 6.84% (advanced) [what's this?] | ||||||||||||||||||||||||||||

| IBU | 39.7 | ||||||||||||||||||||||||||||

| Color | 16.2 SRM | ||||||||||||||||||||||||||||

| Boil Time | 60 min | ||||||||||||||||||||||||||||

| Yeast | White Labs WLP028 (Edinburgh Ale) | ||||||||||||||||||||||||||||

| Fermentables |

| ||||||||||||||||||||||||||||

| Hops |

| ||||||||||||||||||||||||||||

for complete recipe (with details like mash and fermentation temps), click here | |||||||||||||||||||||||||||||

Permalink

Tags for this post: disaster, lost beer, Irish red, ale, red x, redx

Please support BrewUnited by using our Amazon affiliate link when doing any shopping there - be it for homebrewing or for your regular shopping!

1 Comments

Well that's a terrible streak of bad luck.

Hopefully this beer turns out great, the recipe sure does sound good.

posted by muzakx on 1/26/2017 at 09:45:18 AM